Service

Machining of metals

Price of the Service

Category of the Service

Company website

3

products -

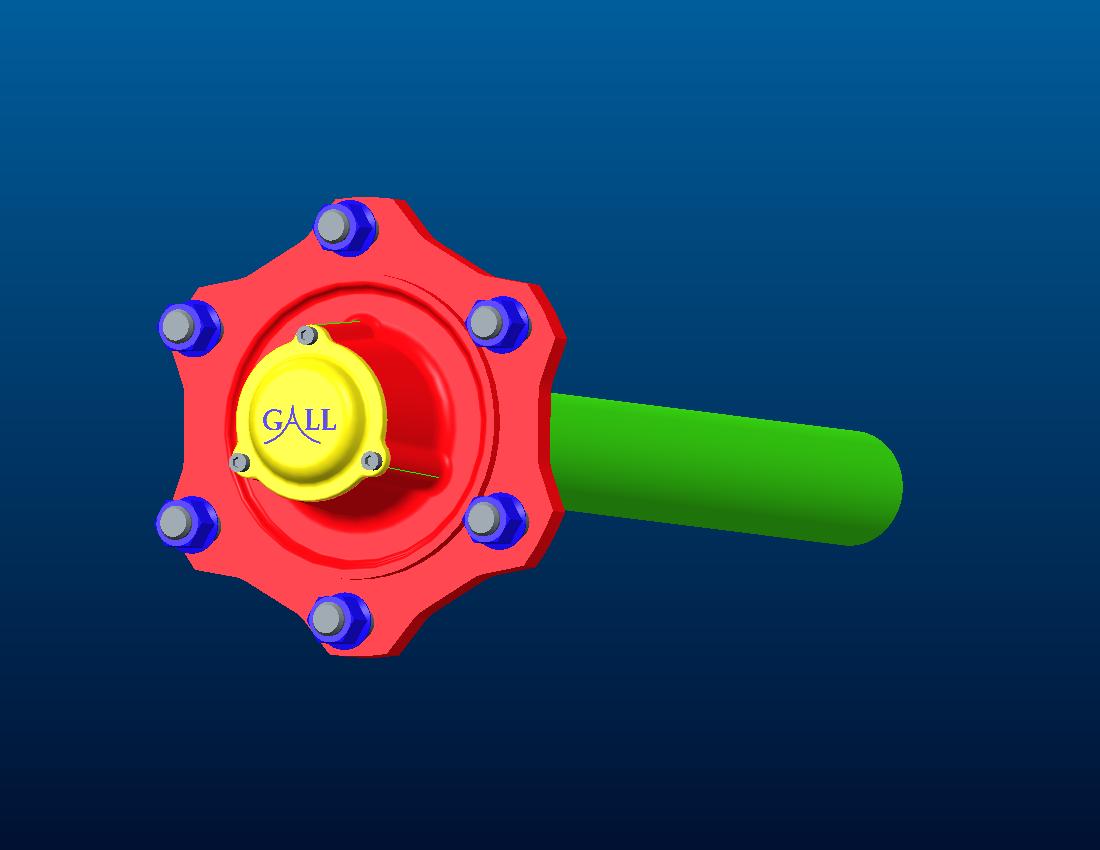

GALL s.r.o.

Our recommended products and services

-

-

Stainless Steel Machining At Soluciones del Mecanizado Bian, S.L., we have extensive experience in the machining of stainless steel components, using state-of-the-art CNC machinery to deliver precise, long-lasting results with top-quality finishes. Stainless steel is one of the most in-demand materials due to its corrosion resistance, hygienic properties, and excellent mechanical performance. It is ideal for applications in industries such as food processing, pharmaceuticals, chemicals, marine, medical, and energy. What does our stainless steel machining service include? CNC turning, milling, drilling, and threading of stainless steel parts. Custom-made components from technical drawings or physical samples: from single units to large production series. Technical advice on selecting the most suitable stainless steel grade (AISI 303, 304, 316, 420, etc.). Application of thermal treatments and surface finishes when required (polishing, passivation, pickling, etc.). Precise dimensional control and technical documentation available upon request. Why choose us for stainless steel machining? ✅ Technical expertise: in-depth knowledge of stainless steel behavior, including hardness, tool wear, and optimal finishing. ✅ Accuracy and quality: our advanced CNC machining centers and lathes ensure tight tolerances and flawless finishes. ✅ Flexible production: from simple parts to complex geometries such as structural components, connectors, shafts, flanges, and more. ✅ Fast and reliable turnaround: we tailor our processes to meet client deadlines without compromising quality. ✅ Multi-sector experience: we work with industrial companies, engineering firms, laboratories, machinery manufacturers, and more. What stainless steel grades do we work with? AISI 303 – Excellent machinability, ideal for threaded parts and good mechanical strength. AISI 304 – High corrosion resistance, suitable for food-grade and industrial use. AISI 316 – Recommended for harsh environments (saltwater, chemical, marine industries). AISI 420 – Hardenable stainless steel, ideal for blades or components exposed to wear.

-

Custom CNC Saw Cutting At Soluciones del Mecanizado Bian, S.L., we offer a custom CNC saw cutting service that ensures precision, efficiency, and quality in the processing of both metal and plastic materials. Thanks to our automated equipment, we perform straight, clean, and deformation-free cuts—ideal for parts that will be machined, assembled, or used directly in industrial applications. This service is perfect for preparing raw material, preforms, semi-finished parts, or final cuts according to technical drawings, especially in projects requiring high repeatability and tight dimensional tolerances. What materials do we cut with CNC saws? Aluminum: profiles, blocks, and sheets in various alloys (6000, 7000 series, etc.). Steel: both carbon and stainless, in bars, rounds, or solid formats. Technical plastics: POM, PA6, PVC, PE, and more. Brass, copper, and other non-ferrous metals. Service features: Straight and perpendicular cuts with tight tolerances. Series cutting with high repeatability. Custom lengths based on customer drawings or specifications. CNC equipment with automatic feed control and cooling systems to extend material life and prevent overheating. Surface finish suitable for subsequent machining, welding, or assembly. Advantages of CNC saw cutting at Soluciones del Mecanizado Bian ✅ Speed: ideal for quickly preparing parts with high production agility. ✅ Dimensional precision: consistent and accurate cuts thanks to CNC control. ✅ Flexibility: we adapt cuts to any length, batch size, or material type. ✅ Integration with other services: we can combine saw cutting with machining, threading, drilling, or finishing operations. ✅ Waste reduction: optimized material use in each cut, minimizing scrap.

-

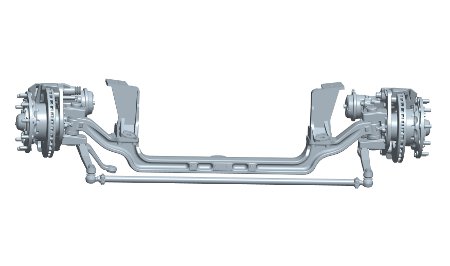

CNC machining under drawings of all types of materials.

-